How to Remove a Rack Label: A Step-by-Step Guide

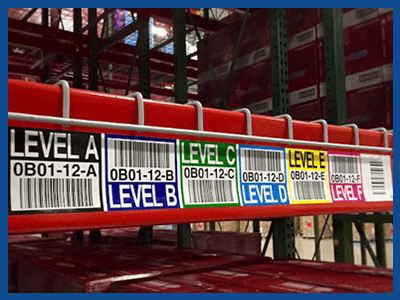

Rack labels are a crucial warehouse management component, tracking products and locations throughout the facility. These labels may need to be removed and replaced due to damage, system changes, or customer transitions in third-party logistics (3PL) environments. Here’s an overview of how to manage rack label removal, the challenges involved, and some alternatives.

Why Would a Rack Label Need to Be Removed?

There are several reasons why a warehouse might need to remove rack labels. If a label is damaged, worn out, or outdated due to changes in inventory systems or warehouse management software (WMS), it must be replaced. In addition, 3PLs often need to relabel racks when their customers change. Expansions, reorganizations, and other operational adjustments also necessitate the removal of old labels to make way for new ones.

Methods for Removing a Rack Label

Removing a rack label can be more challenging than it seems. Scraping off labels is one option, but it’s time-consuming, often taking anywhere from one to five minutes per label to fully clean the surface and prep it for a new label. Chemical removers are another method but can be harsh on both the surface and employees. A third option, heat guns, can sometimes loosen adhesives for easier removal.

Some warehouses hire temporary workers specifically for label removal. Depending on the size of the warehouse and the number of labels to remove, this option can add significant costs and time.

Can You Put a New Label Over an Old One?

It’s possible to apply a new label over an old one. One method is using a cover-up label with a silver backing to prevent the old label from showing through. This works well if the new label is applied in the same spot as the old one. However, applying a new label on top may lead to adhesion issues if the old label is damaged or uneven.

Placing a new label over an old one can also create scan issues. Paper labels are especially susceptible to showing through, while poly labels are better at obscuring the old label.

Using Beam Renew™ for a Refreshed Look

Another alternative is to use Beam Renew™ warehouse relabeling solution. Beam Renew™ provides a cleaner finish by covering the old label entirely and offering a larger surface for the new label to adhere to. This is especially useful if the old label is damaged or if multiple old labels need to be covered.

Placing a new label over an old one can also create scan issues. Paper labels are especially susceptible to showing through, while poly labels are better at obscuring the old label.

Using Clean Release™ or Magnet Labels

To avoid the hassle of label removal in the future, consider using magnet labels or removable labels such as ID Label’s Clean Release™ repositionable labels. Clean Release™ labels are popular because they can be easily removed and reapplied if needed, such as when a beam is damaged, or a layout is changed.

Magnetic labels are another option, particularly for environments like freezers or warehouses with high turnover. Magnets offer flexibility and can be transferred to new locations without any adhesive residue. They are especially beneficial for warehouses that frequently relocate or consolidate operations.

Planning for a Relabeling Project

Relabeling a warehouse is a major project that requires careful planning, especially if the facility is active. Downtime must be minimized, and relabeling often occurs during third shifts or over weekends to ensure a smooth transition. It’s important to factor in the labor costs generated with old label removal, which is often overlooked in the planning stages.

Setting Up for Success

To ensure a smooth relabeling project, start planning months in advance. Working with experienced professionals can help streamline the process and provide solutions that minimize downtime and future headaches. Choosing flexible solutions like Clean Release™ labels from the start can save time and money down the line, especially if the warehouse undergoes frequent changes or system upgrades.

Conclusion

Rack label removal can be a labor-intensive task, but with the right planning and tools, it doesn’t have to be overwhelming. Whether you choose to scrape and remove labels or apply cover-up solutions like Beam Renew™, or you opt for flexible labeling options like Clean Release™ or magnets, there are ways to simplify the process. The key to success lies in careful preparation, understanding your warehouse’s needs, and choosing the best labeling solution for the long term.

The ID Label Advantage

ID Label manufactures extremely durable warehouse rack and bin location labels. Our materials have been tested and used in warehouse operations around the globe.

We also provide warehouse signage and turnkey nationwide installation services to provide a complete solution to our many clients who rely on us for all their warehousing needs.

Interested in learning more? Contact us today.

Tags

Recent Posts

- How to Remove a Rack Label: A Step-by-Step Guide

- Eliminate the Hassle of Removing Outdated or Damaged Warehouse Labels

- The Essential Role Labeling Plays in Food Traceability

- Ask the Expert: Should I Choose Paint or Tape to Mark My Warehouse Floors?

- Scott Bender Joins ID Label as Vice President of Sales