Selecting the Right Label for Cleanroom Applications

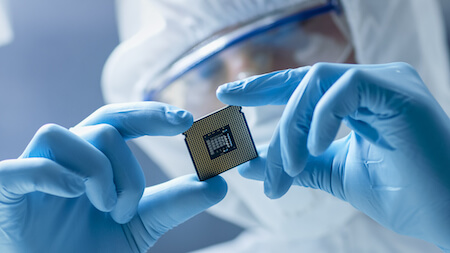

White suits, masks, gloves — sounds like something out of a science fiction movie, doesn’t it?

But these aren’t props in a movie. They’re part of a standard uniform for cleanroom environments.

“Cleanrooms are workspaces with controlled levels of environmental pollutants, such as dust, microbes, aerosol particles, and vapors,” said Jason Golding, operations manager at ID Label.

“Industries ranging from electronics to healthcare require varying degrees of control, which is specified by the number of particles per cubic meter at a specified particle size,” he said.

Our labels are used in many cleanrooms and controlled environments across a variety of industries, including microelectronics, media, biotechnology and pharmaceuticals.

“ID Label’s cleanroom solutions are optimized to ensure contaminate-free printing. Our thermal label materials are designed and engineered to have little to no outgassing properties. And we offer them in a variety of shapes, colors, patterns, and coatings.”

“ID Label’s cleanroom solutions are optimized to ensure contaminate-free printing. Our thermal label materials are designed and engineered to have little to no outgassing properties. And we offer them in a variety of shapes, colors, patterns, and coatings.”

– Jason Golding, ID Label

Cleanroom Labeling Requirements

Labels for cleanroom applications have strict requirements.

“ID Label’s cleanroom solutions are optimized to ensure contaminate-free printing,” Golding said. “Our thermal label materials are designed and engineered to have little to no outgassing properties. And we offer them in a variety of shapes, colors, patterns, and coatings.”

ID Label’s products are used in many cleanrooms and controlled environments across a variety of industries, including microelectronics, media, biotechnology and pharmaceuticals.

Precision-Cleaned Labels and Tags

ID Label follows Good Manufacturing Practices (GMP) to ensure our products are consistently produced and controlled according to industry quality standards. This allows us to offer permanent and removable cleanroom labels and tags of the highest quality—custom-engineered for durability to match your environment.

- Electrostatic ionization to neutralize the triboelectric surface charges

- High-pressure air knife and precision surface cleaning of materials

- Direct thermal materials to eliminate the potential contamination of a ribbon

- Custom-tinted liners for easy identification

- Custom coatings for patterned, tabbed or piggyback constructions

The ID Label Advantage

ID Label adheres to industry Good Manufacturing Practices (GMP) to ensure our products are consistently produced and controlled according to industry quality standards. This allows us to offer permanent and removable cleanroom labels and tags of the highest quality.

We also offer a range of solutions for electronics, PCB and other applications. Contact us to learn more or request samples for testing.

Interested in learning more? Contact us today.

Tags

Recent Posts

- How to Remove a Rack Label: A Step-by-Step Guide

- Eliminate the Hassle of Removing Outdated or Damaged Warehouse Labels

- The Essential Role Labeling Plays in Food Traceability

- Ask the Expert: Should I Choose Paint or Tape to Mark My Warehouse Floors?

- Scott Bender Joins ID Label as Vice President of Sales